| Symptom of malfunction |

|

| Output limit, etc. | Without |

| Malfunction indicator light | Light out |

| Multi information | Engine system failure |

| Possible cause of malfunction | Malfunction of engine sub revolution sensor |

| Symptom of malfunction |

|

| Output limit, etc. | Without |

| Malfunction indicator light | Light out |

| Multi information | Engine system failure |

| Possible cause of malfunction | Malfunction of engine sub revolution sensor |

Detail

- Set the starter key to the "LOCK" position and connect the signal check harness.

- Disconnect the engine sub revolution sensor connector.

- Turn the starter key "ON" and measure voltage between the 3rd and 2nd terminals of the engine sub revolution sensor connector (vehicle harness side).

NO

Go to [2] Measuring voltage between terminals.

YES

Go to [3] Measuring an input waveform of the engine ECU.

Detail

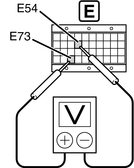

- Measure voltage between the terminals E73 and E54.

ECU terminal No. Description of terminal

Standard value: 4.5-5.5 V

NO

Fault in engine ECU and/or connectorsYES

Faulty harness

Detail

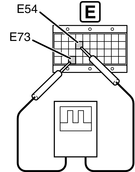

- Set the starter key to the "LOCK" position and connect the engine sub revolution sensor connector.

- Start and then idle the engine.

- Measure voltage between the terminals E54 and E73.

ECU terminal No. Description of terminal

NO

Go to [4] Measuring resistance between terminals.YES

Fault in engine ECU and/or ECU connectors

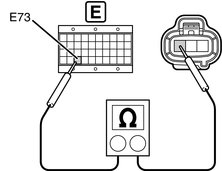

Detail

- Keep the engine sub revolution sensor connector connected.

- Measure resistance between the terminal E73 and the 1st terminal of the engine sub revolution sensor connector (vehicle harness side).

Standard value: 2 Ω or less

NO

Faulty harnessYES

Fault in engine sub revolution sensor

Detail

- Confirm the DTC P0340 is inactive

- Start the engine and let it idling condition.

- Verify the DTC P0340 is inactive.

- DTC Clear

- Clear the DTC with Hino DX

- Confirm the same DTC is not reoccurred

- P0340 is reoccur: Return to first process

- Other DTC appear: Refer to concerned Trouble shooting

Complete